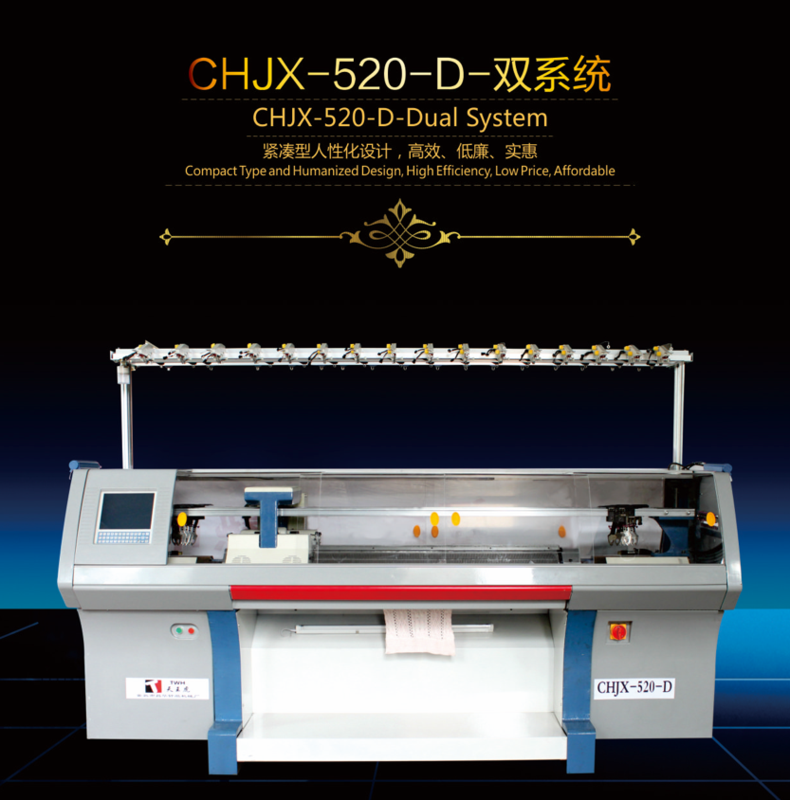

CHJX-520-D-DUAL SYSTEM

CHJX-520-D-DUAL SYSTEM

- 产品详情

- 产品参数

CHJX-520-D-DUAL SYSTEM

SPECIFICATIONS

Guage available

5G,7G,10G,12G,14G,16G

Knitting width

52INCH,56INCH,50INCH,80INCH

Knitting Speed

Controlled by sever motor with 64 speeds optional, max1.2m/s. the servo motor combines precise feedback control system withhigh-speed digital signal processor(DSP) to control IGBT to achieve accurateelectric current output.

Knitting system

Single carriage/singlesystem; single carriage/double system

Knitting function

Stitch transfer, tuck, pointelle, intasia, jacquard,apparent (unapparent) binding-off and other regular patterns.

Racking system

Controlled by AC servo motor, with programmable racking rangeof up to 2 inches, in addition to accurate fine-tune capability.

Needle detection alarm device

Capable of all-dimensional needle detection alarming, abreakthrough compared to current simplistic side-to-side needle detection alarming systems.

Needle recognition

Advanced encoder adopted

Stitch transfer

Triangular integrated designing enables independent or simultaneous transfer for single or double system. Simultaneous transferringand knitting can be done for double system machines to realize more efficientproduction.

Stitch density

Controlled by stepping motor with 24 density options.

Sinker system

Controlled by stepping motor, adjustable to differentfabrics to realize multiple binding-off and stitch-dropping effect.

Comb device

Adopting close-end U-shaped composite needles which can bereleased freely to hold and deliver yarns.

Yarn cutter and gripper

Including 4 grippers and 2 cutters that are separatelycontrolled by 6 motors, programmed instructions can be carried oursimultaneously or separately to improve work efficiency and reduce yarnwastage.

Take-down roller infrared alarm

Programmed instructions controlled by stepping motor, 24levels of pull force optional.

Yarn carrier

2*8 yarn carriers on both sides of 4 guide rails. Shiftableat any position of the needle bed(special intarsia carriers optional)

protection system

the machine alarm system will set off when yarn-breaking,knots, floating thread, rewinding, end of knitting, racking failure, needlebreakage or wrong programming occur. Safety auto-lock protection enabled.

Control system

1. LCD touch screen, graphical interface, USB andnetwork compatible, with expanded memory of up to 1G. A great amount ofpatterns can be stores and mobilized for use at any time as per production requirements.

2. Monitoring display: Various operating parameterscan be displayed and can be adjusted anytime when the machine is running,making operations as convenient and time-saving as possible.

3. Design system and control system (software) areeasy to update for free.

4. Multi-language operation system: there areChinese, English and Arabic versions. Languages can be switched according tocustomer requirements

Network

High speed network can coordinate up to 250 machines; theknitting data can be uploaded downloaded and shared.

Power system

Single-phase 220V and triple-phase 380V; adopting advanced CMOS technology enabling memorizing at the instant of power outage and restoringof knitting thereafter.

Volume and weight

L*W*H 2750*920*1900MM

NW 800kgs